Bin lifters to ease waste sorting and recycling

Lifting units to ease waste sorting and recycling

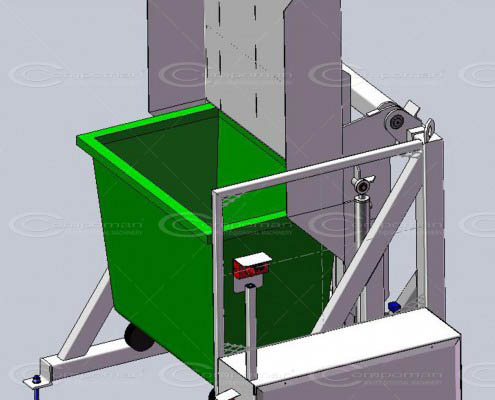

Using a separate bin lifter is useful when you have bins and containers for different types of waste and when you perform waste sorting right at the place where waste is created.

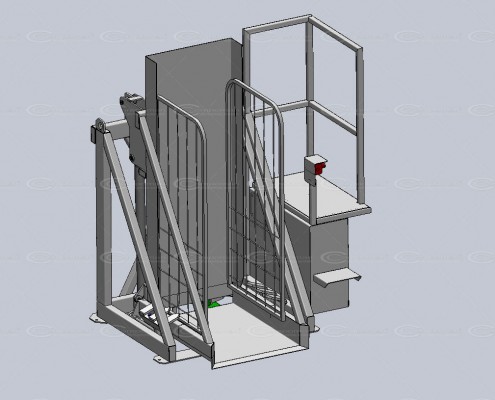

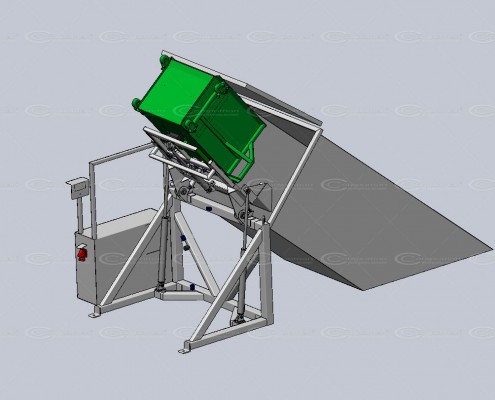

Any lifting unit eases and speeds up the emptying of waste bins into a container, waste compactor or garbage truck. Using lifting unit increases safety and prevents accidents at work that are caused by lifting and kipping too heavy waste bins.

Moving the unit is made easy

The separable lifting unit moves either on wheels or on rails easily from one compactor or container to another. Such an appliance only weighs as little as 250 kg or even less – moving it on wheels or rails makes it easy to change the unit position from one workplace to another.

The lifting unit can also be fixed to a ramp. On such occasions it is possible to switch mobile compactors at this location and the lifting unit is always available.

Lifting capacity and speed on order

The lifting capacity of a machine is 200 kg in the standard configuration. We can increase the lifting capacity up to 500 kg and more depending on need. Lifting speed can be adjusted within a certain range according to customer request.

Thus capability to service different types of bins and heavy bins makes our lifting units flexible tools in a complicated environment.

Electric motors used on the standard machines are rated at 0,75-1,5 kW. Our special projects are made with electrical motors rated up to 4 kW depending on the needs of location and type of bins.

One bin lifter can empty various sizes of bins – from 190 to 370 liters and even as big as 660 to 1100 liters. The lifting height can in the standard configuration range from 1,2-2,0 meters.

Safety on work place

The bin lifter can be built for moving on guiding rails. This secures the working environment and helps to avoid accidents.

A bin lifter works only if the user has turned it on at the right place. A specially-installed green light illuminates when all security steps have been followed and only then is the bin lifter ready to lift and empty the waste bin.

Our bin lifters are also equipped with a cable winder so there will be no cable on the floor, improving work environment safety further.

The safety cage around the bin lifter can be electrically interlocked.

| Standard KIP units | El motor | Bin volume | Lifting capacity | Lifting height | Weight | Lower bin lifting balk | Upper bin fixing balk |

| KIP-1200 | 0,75 kW | up to 660l | 200 kg | 1200 mm | 310 kg | 900 mm | 1100 mm |

| KIP-1200 E | 3,0 kW | up to 1100l | 400 kg | 1200 mm | 600 kg | 900 mm | 1100 mm |

| KIP-1600 | 1,5 kW | up to 660l | 200 kg | 1600 mm | 335 kg | 900 mm | 1270 mm |

| KIP-1600 E | 3,0 kW | up to 1100l | 400 kg | 1600 mm | 650 kg | 900 mm | 1270 mm |

| KIP-2000 | 1,5 kW | up to 660l | 200 kg | 2100 mm | 360 kg | 900 mm | 1470 mm |

| KIP-1200 for cardboard carts | 3 kW | cardboard carts | 200 kg | 1200 mm | 800 kg | – | – |

| KIP-1600 for cardboard carts | 3 kW | cardboard carts | 200 kg | 1600 mm | 900 kg | – | – |

Advantages of Compoman bin lifters

- Lifting capacity to order.

- Work cycle speed to order.

- Safety cage can be interlocked.

- Safe two-hand operation.

- Lifting range from 1,2 m to 2,0 m.

- Can service bins from 140 L to 1100 L.

- Fixed to ramp or moving on wheels.

- Can be installed to move on rails.

- Possible to connect with weighing system.

- Can be manufactured using stainless steel.

- Colour coating of your choice.

- Many types of paint available, for example paint suitable in salty air and maritime climate.