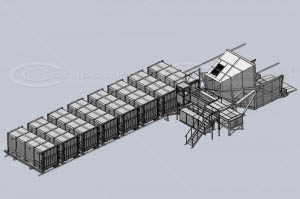

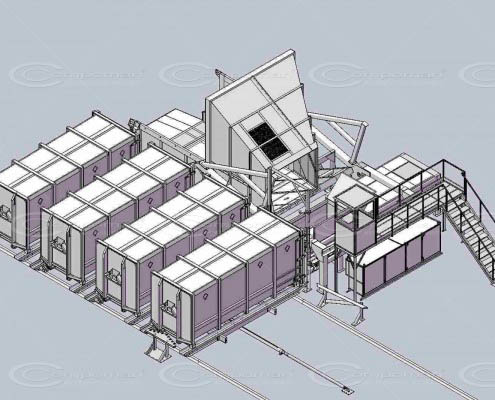

Waste Transfer Station with Big Lifting Hopper

Compoman Waste Transfer Station with Big Lifting Hopper®

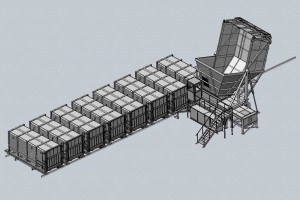

This is a smart waste transfer station giving you high level of volume reduction and a 3-5 times rise in waste transferring volumes per day.

Compoman Big Lifting Hopper® allows emptying waste collector truck at once

With the Compoman Big Lifting Hopper®, the waste collector truck can be sent back where it belongs – collecting waste in its service area!

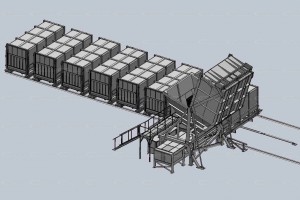

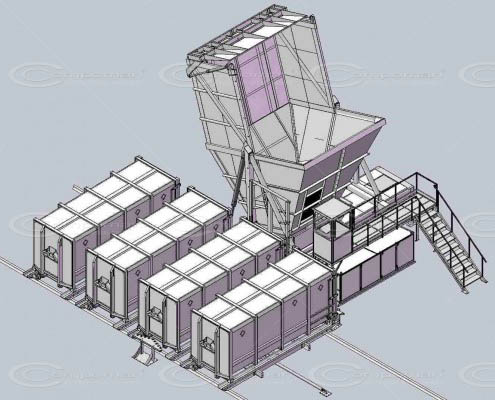

Compoman has devised the Big Lifting Hopper® which can fit up to approximately 20-40 m³ of mixed waste in the hopper.

The waste collection truck can be emptied at once into the Big Lifting Hopper® which then begins the process of emptying itself and reloading waste into containers.

The waste truck will in the meantime already have returned to waste collection area!

Easy-to-install WTS

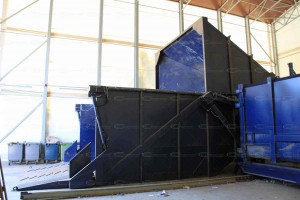

The Compoman Smart WTS with Big Lifting Hopper® is easy and to install on flat surface – no artificial mounds are needed. A concrete platen with mounted beams made according to Compoman drawings is needed beneath the equipment.

The Compoman Smart WTS may be located in towns and settlements. A construction can be built above the station making it weather-proof and also safeguarding it from birds and animals. The Compoman transfer station can easily be combined with sorting factory.

Little space for great volume reduction

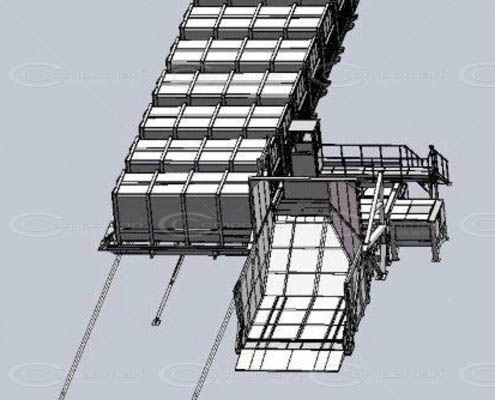

A station with for example four containers needs 15 m x 24 m space plus manoeuvring space for trucks around the station; and a station with eight containers requires a 16 m x 51 m area, plus manoeuvring space for trucks around the station.

The straight cylinder compactor option offers a strong pressing force ensuring great volume reduction of different types of waste. Containers are filled with the waste compactor at a pressure of 400-500 kN (40-50 tonnes or more) thus saving on transportation costs by remarkably reducing waste volume.

How does a Compoman Waste Transfer Station with Big Lifting Hopper work?

Effective and rapid waste reloading

The Big Lifting Hopper® can accommodate the contents of one or more waste collection trucks. The volume of waste in the hopper can range from 20-40 m³, depending on waste type.

Even the biggest waste collection trucks can empty themselves into the Big Lifting Hopper® in one go. This enables the swift return of the waste trucks to their collecting rounds.

Any rise in waste transferring volumes per day depends on the type of waste and logistical schemes in use before the installation of Compoman Smart WTS and any changes made afterwards.

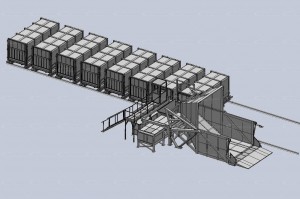

The transfer station can be built using a different number of containers

Containers can be different sizes and adjusted for different types of loading and transporting needs.

Changing containers has been made easy and quick. Containers will be moved to and from the compactor with an automatic container shifting system, which changes containers on special wagons which move on rails.

The Compoman Smart WTS boasts a hydraulic container locking system with hydraulic container closing plates.

Only one person needed to operate whole station

The waste compactor, Big Lifting Hopper® and the movement of containers are operated and controlled by a computer.

Only one person is sufficient to keep an eye on the whole station.

The most important characteristics of Compoman WTS

- Big rising and Lifting Hopper® with approximately 20 m³ – 40 m³ net capacity.

- Rise in waste transferring volumes per day up to 3-5 times.

- High level of volume reduction.

- Possibility to use 20 m³- 37 m³ transfer station containers.

- Easy automatic container closing, shifting, coupling and opening system.

- Needs one person to operate whole station

- Cuts staffing and space costs considerably.

- Long-lasting robust construction and build.

- Easy maintenance.

- Low installation and maintenance costs.