Static compactors

Solutions for demanding locations with impressive volume reduction capabilities

Compoman specializes in the production of made- to-order waste handling static machines with high compaction power that can be built in the same time and to the same price as standard models.

Customized products for the same price as standard products

A wide range of extras and modifications allows the customization of our static compactor to meet your specific requirements. You can set together the machine you need from the components in out options list.

Customization options include such details as type of hopper and bin lifter, container size and container standard, positioning details, motor and hydraulic power, and special paint specifications.

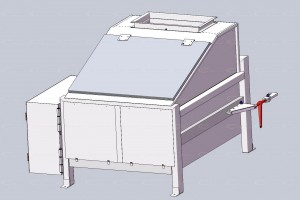

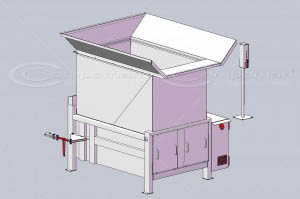

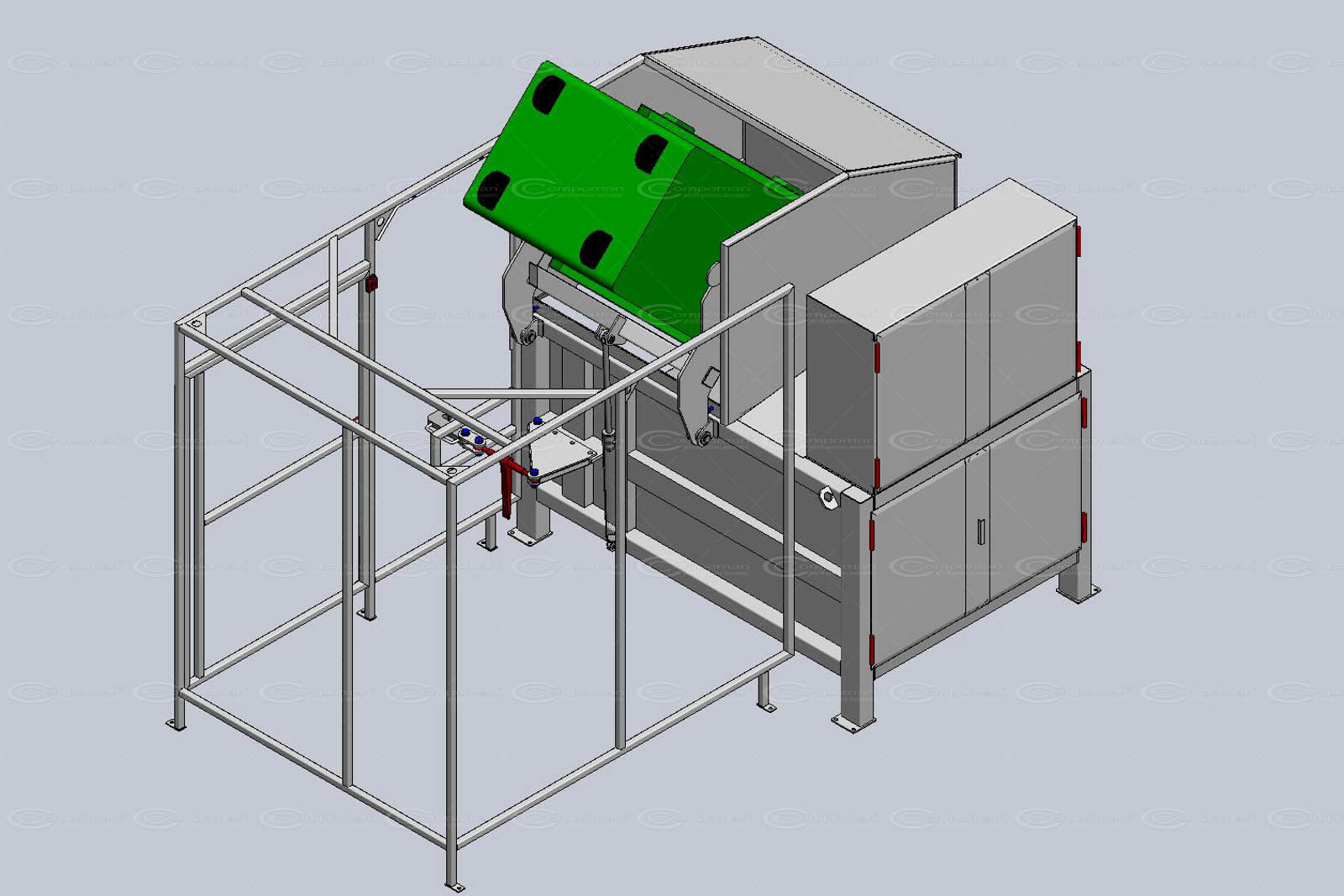

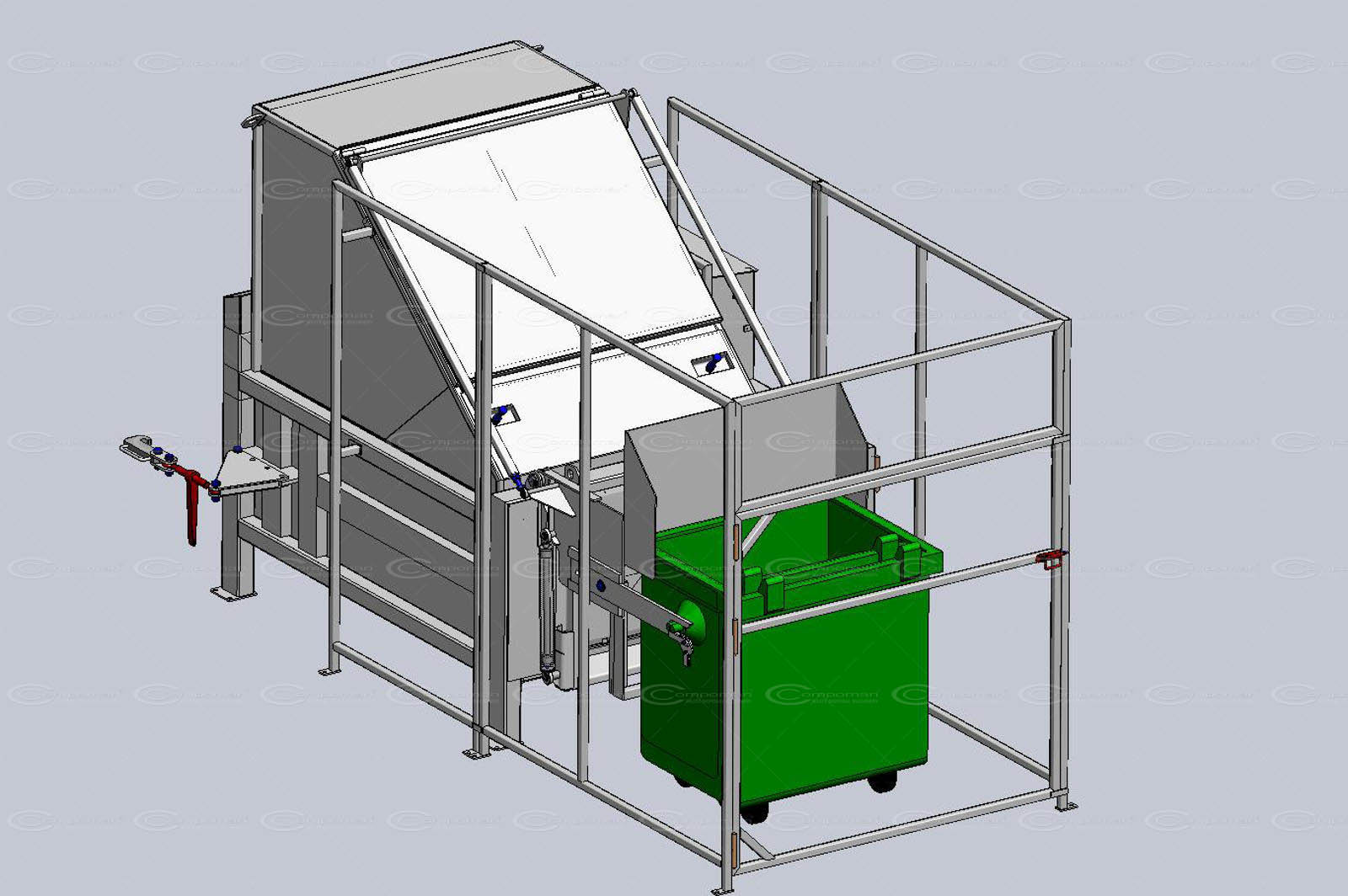

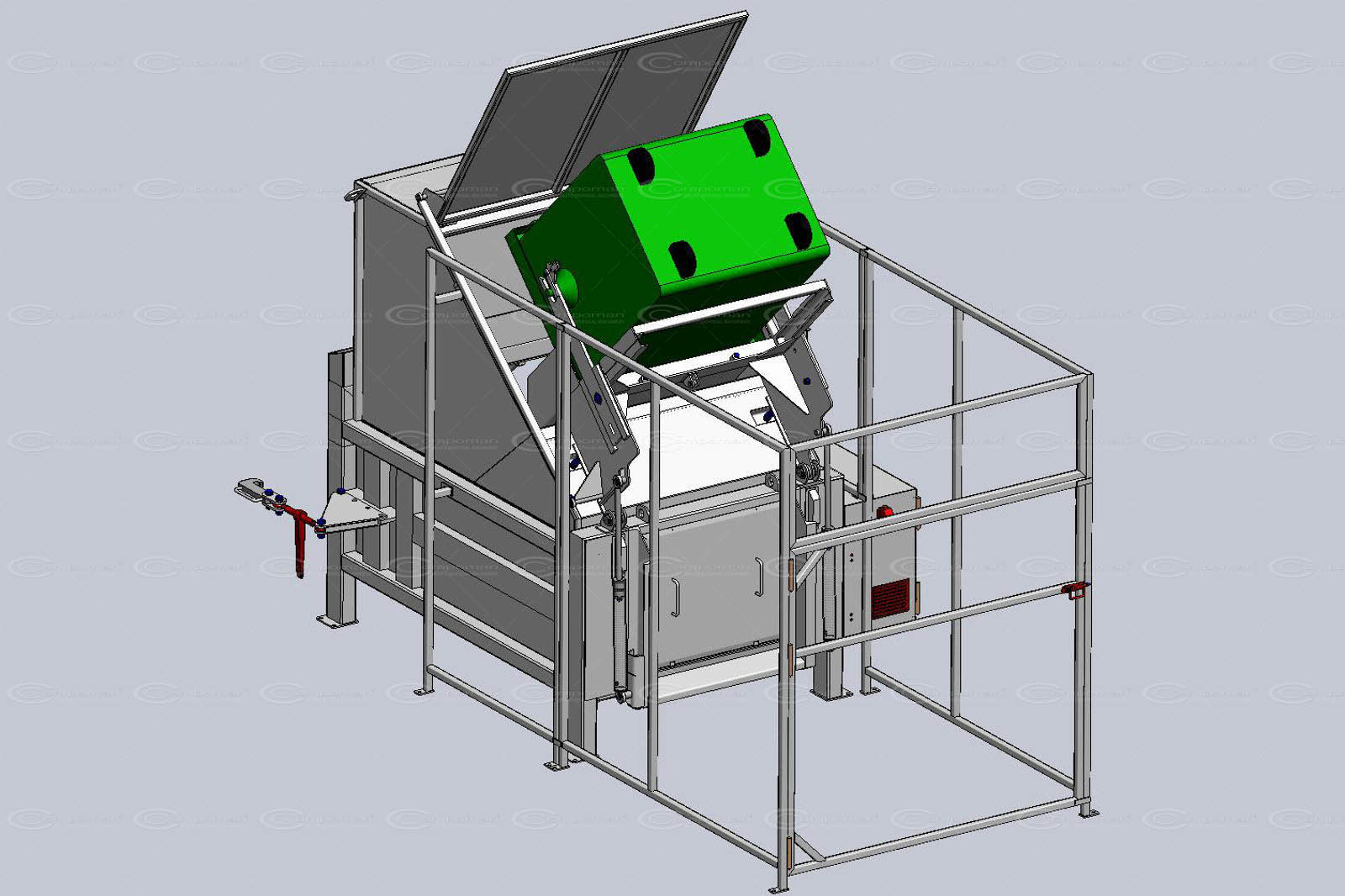

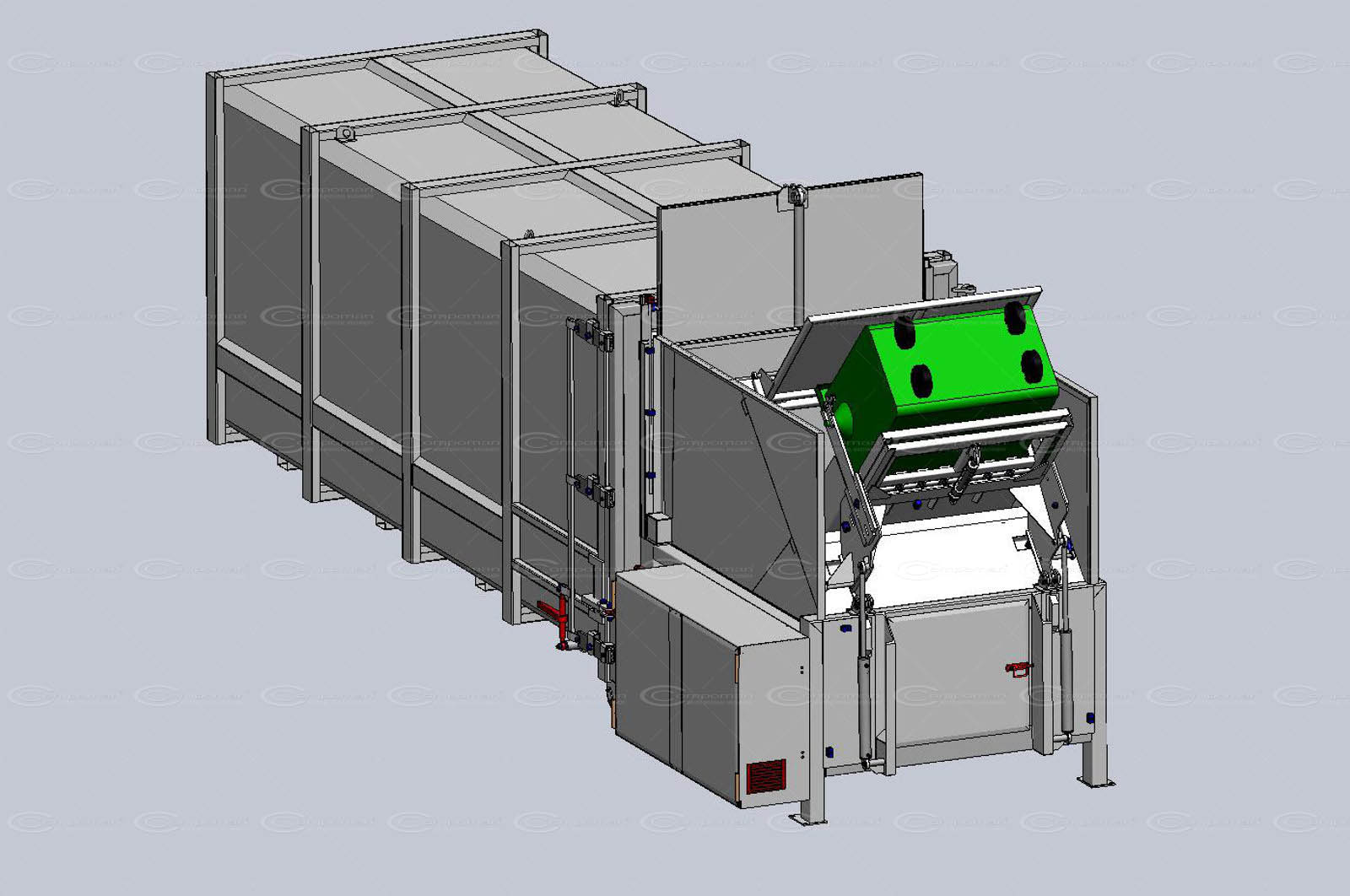

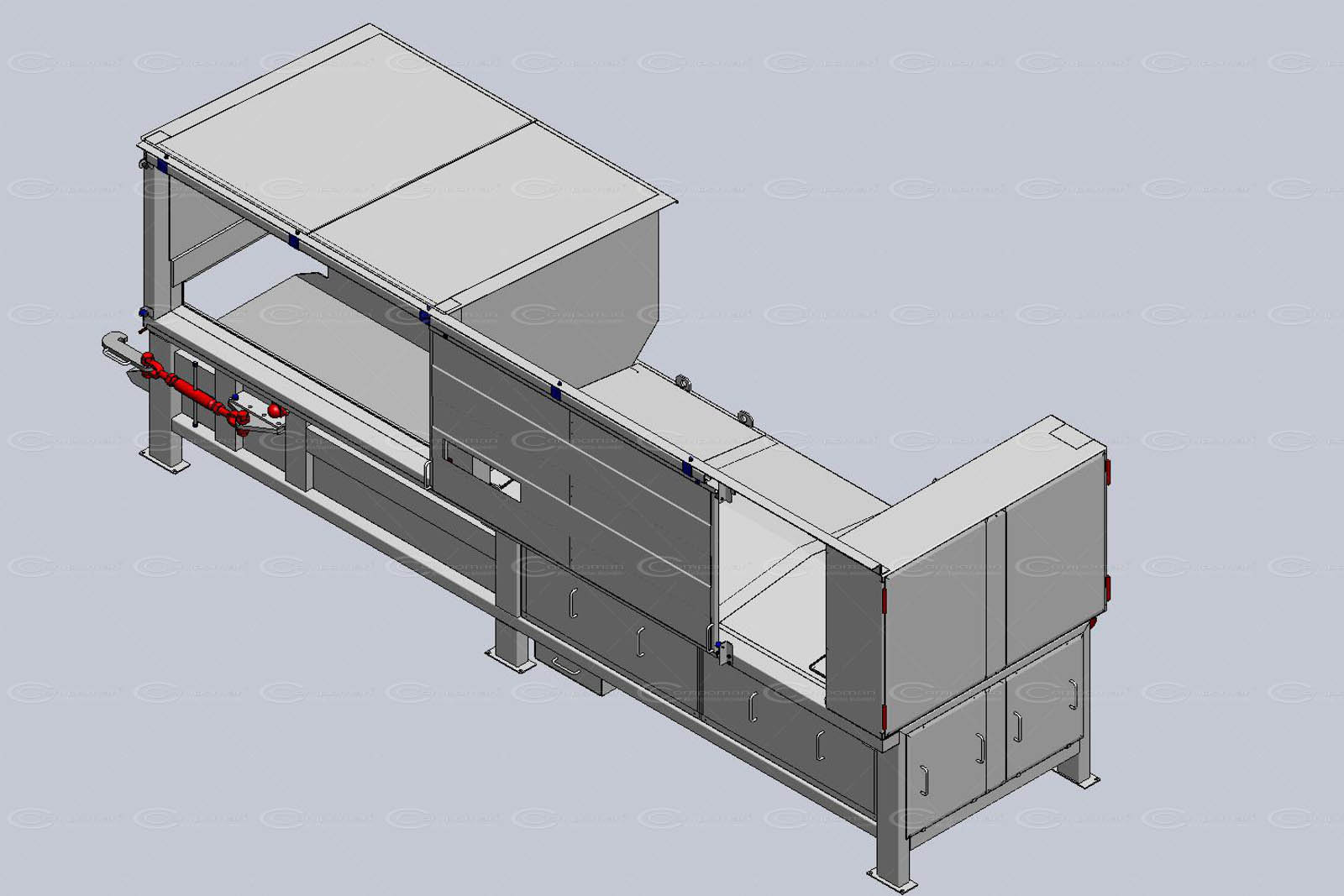

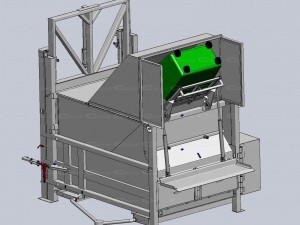

Crossed-cylinder compactors

Crossed-cylinder static compactors are perfect for industrial waste collection and volume reduction use in large stores, hypermarkets, light industry or factories – for spaces where waste volumes are high and space is limited. Local authority can use crossed cylinder static machines also to set together small waste sorting and transfer stations.

Crossed-cylinder static compactor motors range from 5,5kW to 15 kW or higher with pressing forces of 30 to 40 tonnes (or higher if required).

Large loading aperture – small machine footprint

The most important advantage of the crossed cylinder static compactor allows a large loading aperture with only a small machine footprint.

The static compactor can be built to be fed either from a platform, the ground or through a wall-mounted chute.

| Basic crossed cylinder static units | Dimensions of unit in mm | Technical data | ||||||||

| Width | Length | Min loading height | Feed opening | Motor kW | Cylinder | Ram height in mm | Capacity per stroke m³ | Cycle sec | Capacity per hour m³ | |

| X1510 | 1716 | 2090 | 1200 | 1500×1000 | 5,5 | 2x 100/60 | 575 | 0,9 | 66,6 | 46,6 |

| X1511 | 1716 | 2500 | 1300 | 1510×1100 | 5,5 | 2x 100/70 | 635 | 1,1 | 73,3 | 51,8 |

| X1513 | 1716 | 2500 | 1450 | 1510×1280 | 5,5 | 2x 100/70 | 750 | 1,4 | 73,3 | 71,2 |

| X1613 | 1815 | 2500 | 1200 | 1600×1300 | 5,5 | 2x 100/60 | 575 | 1,2 | 84,5 | 51,0 |

| X1812 | 2016 | 2500 | 1200 | 1800×1200 | 5,5 | 2x 100/60 | 575 | 1,2 | 80,3 | 55,7 |

| X1815 | 2016 | 2950 | 1200 | 1800×1500 | 7,5 | 2x 100/70 | 575 | 1,6 | 66,0 | 84,7 |

| X2018 | 2216 | 3400 | 1200 | 2000×1800 | 11 | 2x 125/90 | 575 | 2,1 | 127,6 | 58,4 |

| X2019 | 2216 | 3400 | 1425 | 2000×1920 | 11 | 2x 125/90 | 800 | 3,1 | 127,6 | 86,6 |

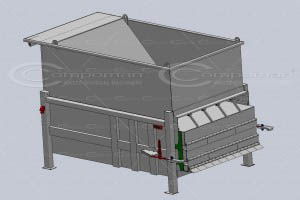

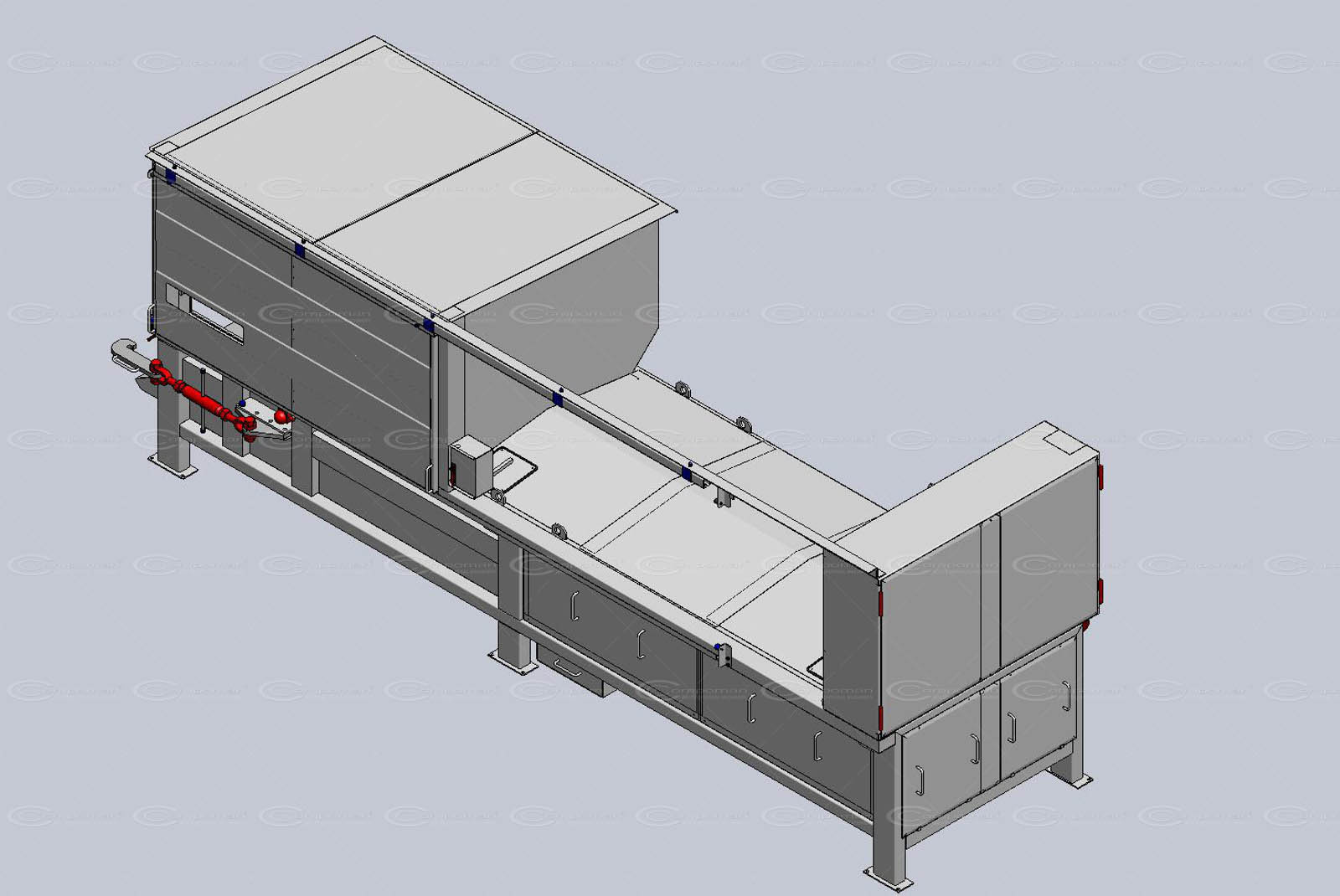

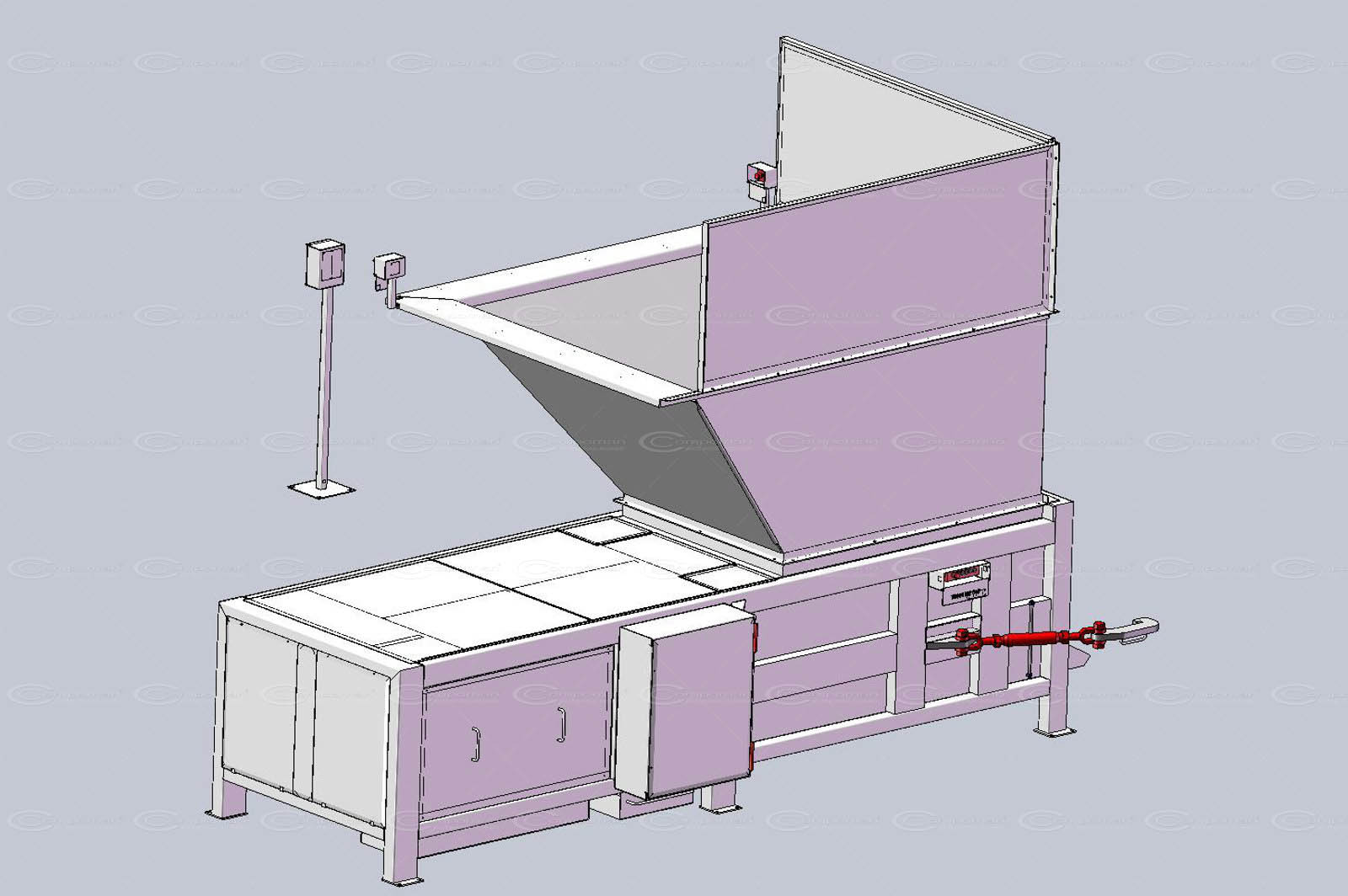

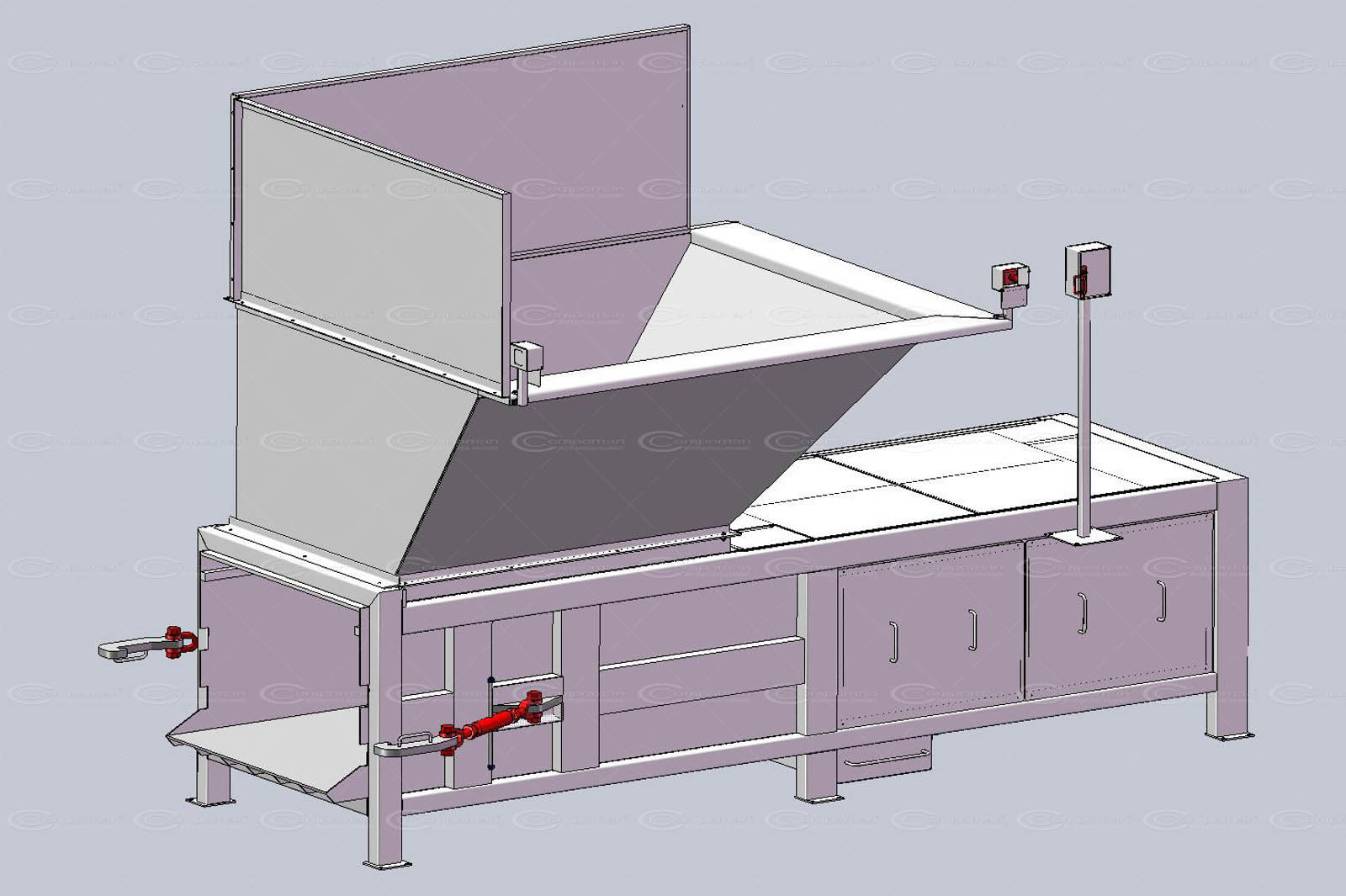

Long-cylinder compactors with compaction forces up to 70 tonnes

Long-cylinder static compactors are perfect for industrial sites or for local authority recycling centres or transfer stations.

The high level of pressing power from the long-cylinder static compactor ensures a high compaction rate and impressive volume reduction to keep waste disposal and transport costs as low as possible.

Long-cylinder static compactor motors range from 5,5 kW to 22 kW with compaction forces from 30 to 70 tonnes.

Accessories such as guide rails, bin-lifters or flanges for connecting to chute systems and air-blown systems are all customizable to the specific site.

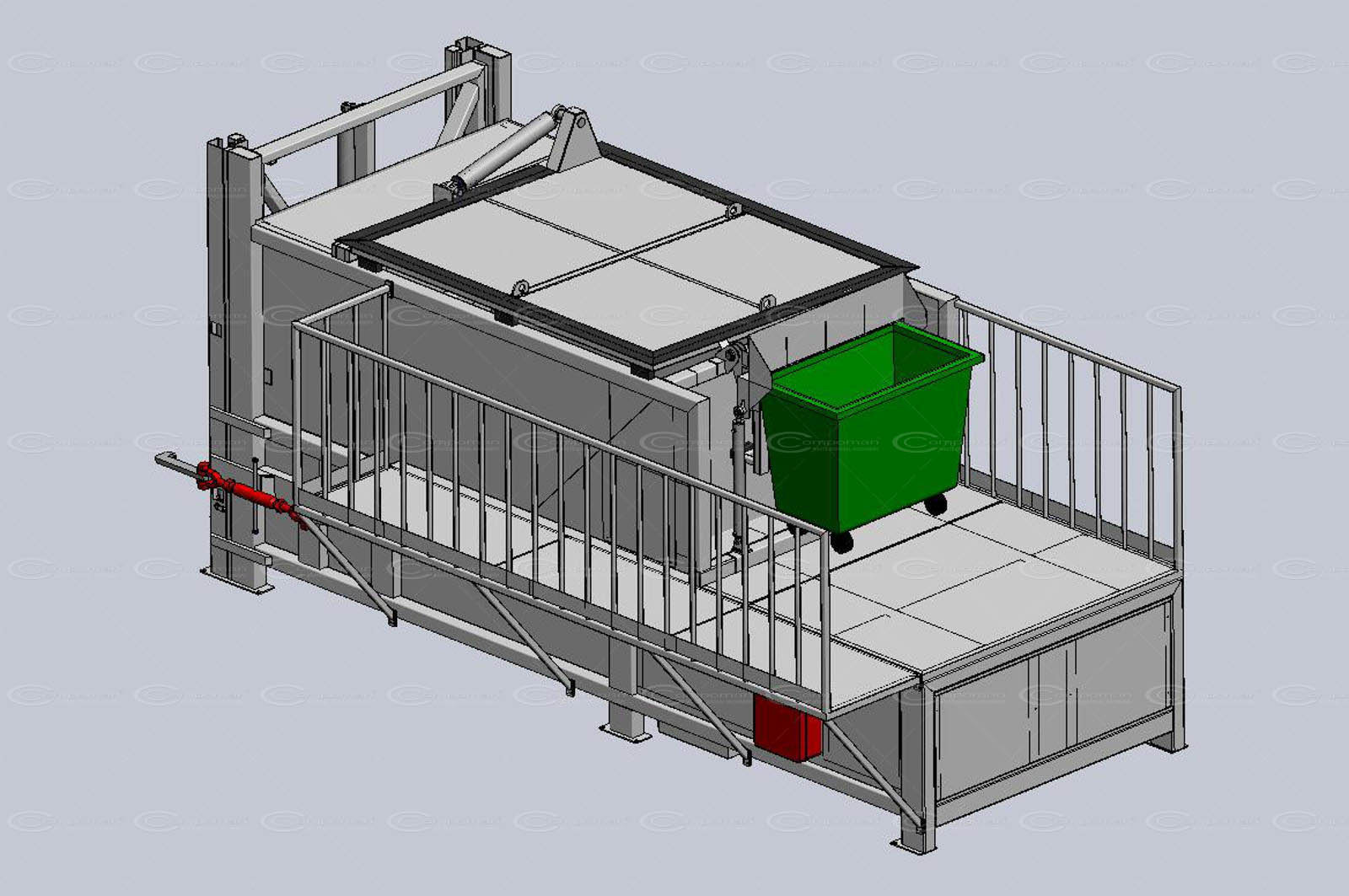

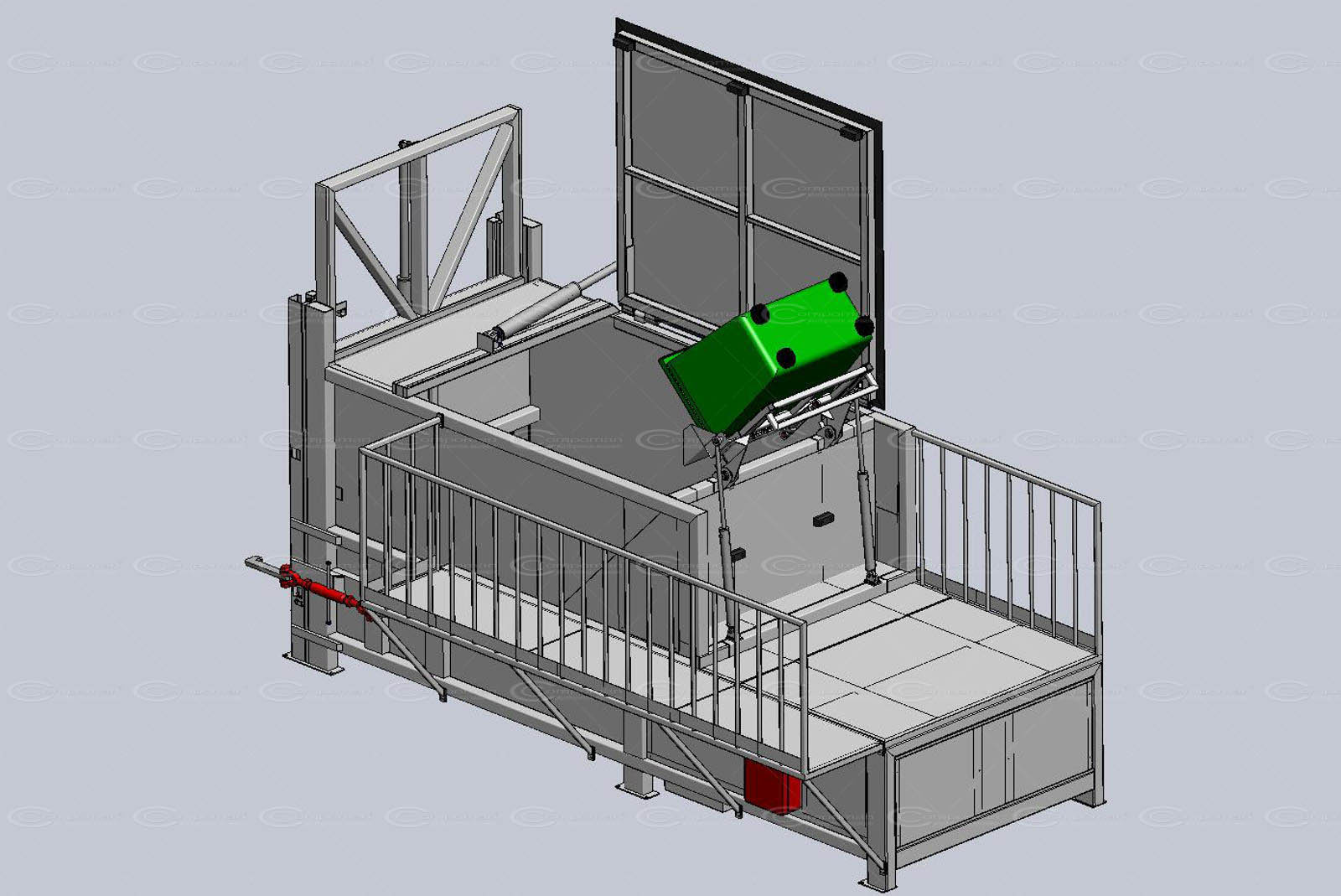

Optional additions include bin-lifters for loading from the ground and from platforms, for different types and sizes of bins.

We can adjust the compactor to the site through add-ons such as increased compaction force or a variable displacement pumps ensuring optimal cycle speed and time.

| Basic long cylinder static units | Dimensions of unit in mm | Technical data | ||||||||

| Width | Length | Min loading height | Feed opening | Motor kW | Cylinder | Ram height in mm | Capacity per stroke m³ | Cycle sec | Capacity per hour m³ | |

| I1514 | 1785 | 4130 | 1290 | 1500×1400 | 11 | 140/90 | 820 | 1,7 | 66,7 | 92,3 |

| I1515 | 1730 | 4370 | 1455 | 1500×1500 | 18,5 | 160/90 | 820 | 1,9 | 70,8 | 94,1 |

| I1521 | 1776 | 5600 | 1420 | 1500×2100 | 18,5 | 160/90 | 813 | 2,6 | 80,5 | 114,5 |

| I1525 | 1776 | 7100 | 1225 | 1500×2500 | 18,5 | 160/90 | 575 | 2,2 | 98,9 | 78,6 |

| I1510 | 1776 | 3555 | 1225 | 1500×1000 | 5,5 | 2x 100/70 | 575 | 0,9 | 87,1 | 35,6 |

| I1515 | 1776 | 4555 | 1225 | 1500×1500 | 11 | 2x 100/70 | 575 | 1,3 | 75,8 | 61,4 |

| I1812 | 2076 | 3955 | 1225 | 1800×1200 | 7,5 | 2x 100/70 | 575 | 1,2 | 83,5 | 53,5 |

| I1815 | 2076 | 4255 | 1225 | 1800×1500 | 11 | 2x 100/70 | 575 | 1,6 | 72,1 | 77,5 |

| I1820 | 2076 | 5720 | 1225 | 1800×2000 | 18,5 | 160/90 | 575 | 2,1 | 83,3 | 89,5 |

| I1825 | 2076 | 6250 | 1450 | 1800×2500 | 18,5 | 160/90 | 800 | 3,6 | 98,9 | 131,0 |

| I2020 | 2280 | 5720 | 1225 | 2000×2000 | 18,5 | 160/90 | 575 | 2,3 | 83,3 | 99,4 |

| I2023 PreCr | 2280 | 6111 | 1350 | 2000×2300 | 18,5 | 160/90 | 700 | 3,2 | 91,4 | 126,8 |

| I2025 | 2280 | 6720 | 1300 | 2000×2500 | 18,5 | 160/90 | 575 | 2,9 | 95,6 | 108,3 |

| I2025 | 2280 | 6720 | 1350 | 2000×2500 | 18,5 | 160/90 | 700 | 3,5 | 95,6 | 131,8 |

| I2035 | 2350 | 9300 | 2700 | 2000×3500 | 75 | 250/180 | 1000 | 7,0 | 60,0 | 420,0 |

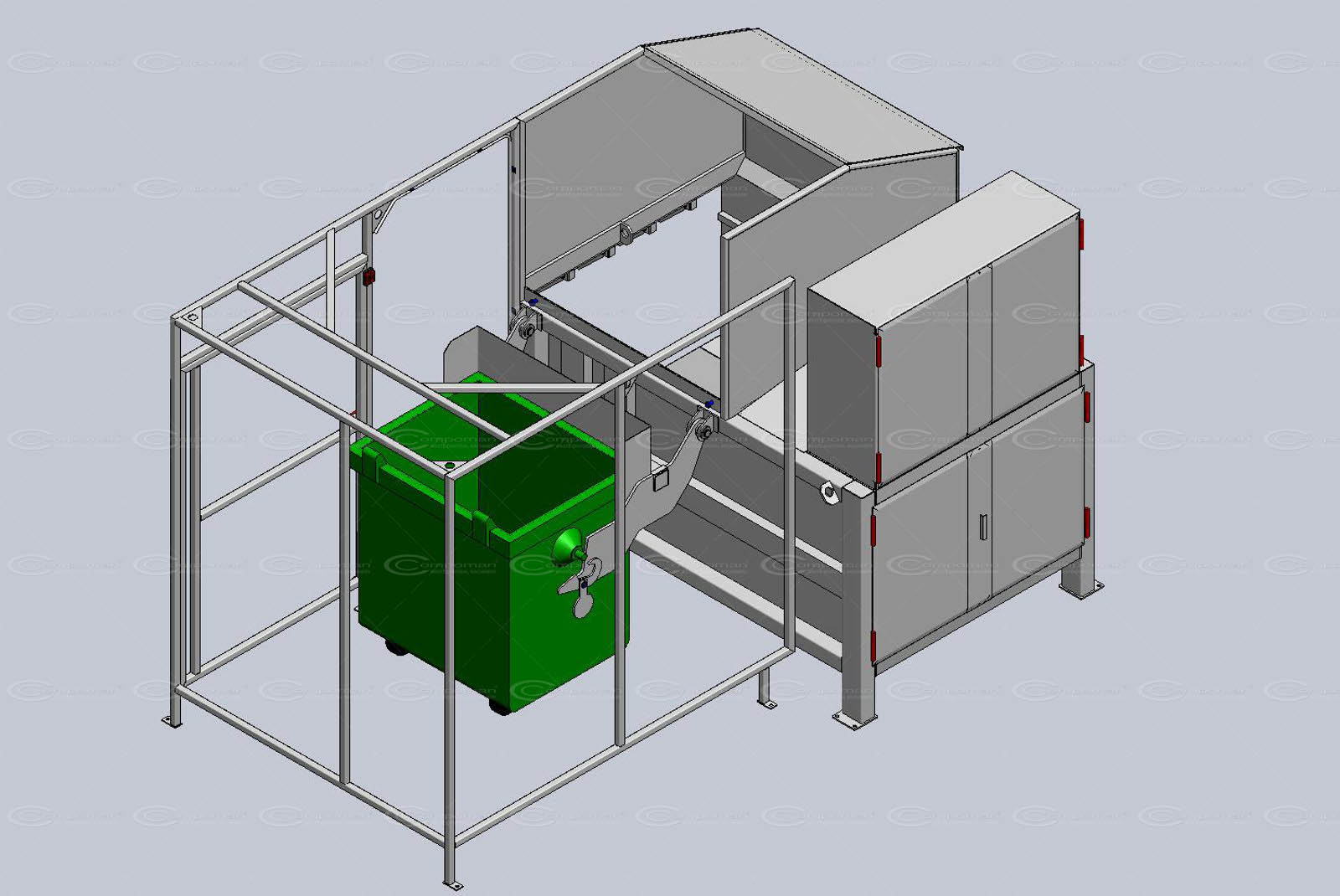

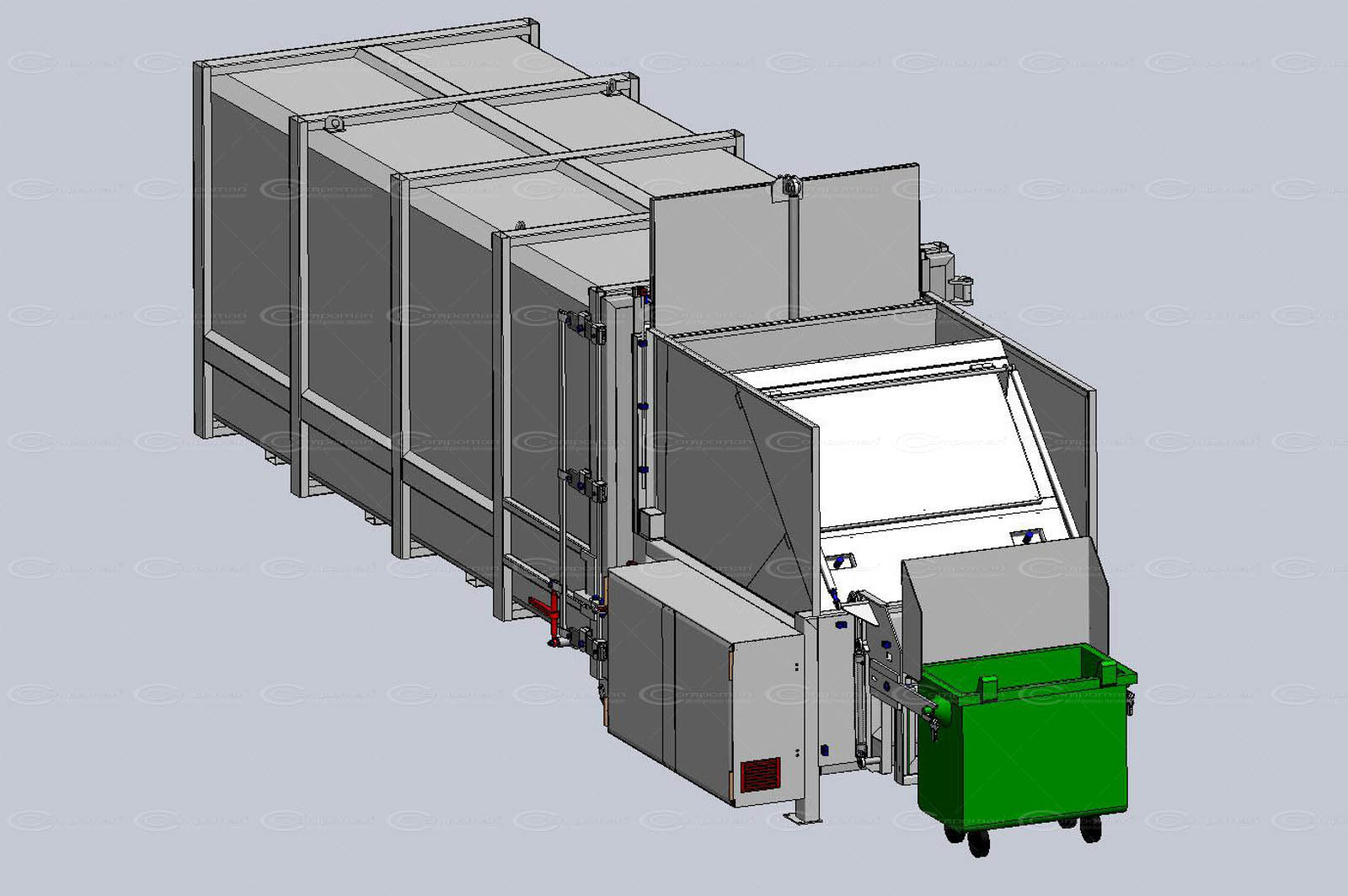

Rail-mounted traversing long-cylinder compactors

Traversing waste compactors are ideal for local transfer stations or household recycling centres or in sites with limited maneuverability for vehicles.

The traversing compactor can service several containers in a row and can include hydraulic docking. Power to the compactor can be through a cable-winding mechanism or via a catenary system. Read here more about our traversing solutions.

Variable size of containers

Containers for the static compactor can be in sizes 20 m³ up until to 37 m³ and more depending on maximum dimensions of the container.

Compoman can build to the standards of several countries and they come equipped for transport either with hook lifting or cable lifting systems.

Compoman can build to the standards of several countries and they come equipped for transport either with hook lifting or cable lifting systems.

Compoman can also produce containers with various non-standard dimensions. Containers can have floating roof.

In the picture on the right you can see a 15 m³ dark blue container with the following measurements – length 6225 mm, height 1600 mm and width 2550 mm.

| Standard containers | |||

| Net capacity | Length mm | Width mm | Height mm |

| 20 m³ | 4480 | 2550 | 2670 |

| 22 m³ | 4880 | 2550 | 2670 |

| 24 m³ | 5280 | 2550 | 2670 |

| 26 m³ | 5680 | 2550 | 2670 |

| 28 m³ | 6080 | 2550 | 2670 |

| 30 m³ | 6480 | 2550 | 2670 |

| 32 m³ | 6680 | 2550 | 2670 |

| 35 m³ | 6400 | 2600 | 2990 |

Optional equipment

- Custom-made loading hoppers.

- Ram and charge box made with specially strengthened and wear-resistant steel.

- Ram and charge box made with corrosion-free steel.

- Ram made with special steel and without plastic wear plates to reduce maintenance costs.

- 100% full indicator and/or adjustable 75-80% full indicator and/or monitoring filling up of the container from 0% to 100%.

- Photocell or ultrasound sensor to start compacting process when charge box is full.

- Lifting unit at front or side, from the ground or from a platform, for customer-specific bins with lifting speed and lifting capacity to order.

- Short or long guide rails or guiding plate to help the easy and repeated placing of the container

- Colour coating of your choice, many types of paint available.

- Floating container roof.

Optional solutions in hydraulics

- Hydro oil cooling assures that your compactor will withstand constant heavy duty use.

- Hydro oil heating keeps your compactor working when temperature is below zero.

- Double pump or bypass system – decreases cycle time

- Variable displacement pump ensuring optimal cycle speed and time.

- Lifting unit at front or side, from the ground or from a platform, for customer-specific bins with lifting speed and lifting capacity to order.

- Pre-crush plate (also with teeth) or wood crushing compactor option.