Mobile compactors

Mobile waste compactors by Compoman have been appreciated by customers all around the world as reliable compacting machines. Mobile waste compactors can be used wherever there are high volumes of waste or recyclable raw materials to be handled.

Individual solutions for different industries

Our waste compactors reduce household and industrial waste volumes as well as paper and other recyclable fractions to 1/6 of the origin volume, thus reducing the transportation and disposal costs.

We have designed individual solutions for many different industries, such as food industry, plastic industry or printing houses. Apart from machines for individual waste disposal, we also offer machines for fast and smooth ring exchange. These “ring-exchange” machines have the same standardised equipment and can therefore be exchanged one against the other without any problems.

To handle waste with high fluid content, a special design of our waste compactors can be used.

Our wet waste compactor and your other choices for collecting wet waste

Our wet waste compactor is an ideal watertight solution for wet waste, such as waste produced in hotels, canteen kitchens, old people’s homes or hospitals. Due to the efficient locking system, the wet waste compactor is absolutely liquid-tight. Thanks to the self-cleaning press-ram and the tub-shaped design of the press head, cleaning the compaction chamber becomes unnecessary. Read here more about our wet waste solutions.

Self-driving compactors for special locations

Mobile waste compactors can be made driving out from the location, when the cellar ceiling is low or door is too narrow for the waste truck.

Self-driving waste compactors are our solution between full size portable compactor and standard wheelie bins. Driving compactors can drive out of the loading place because they do have own battery set and they are able to drive for 10-15 minutes using battery resource.

Our self-driving compactor is watertight and therefore suitable for the low cellar waste rooms in the basements of large residential blocks or shopping malls. Read here more about our self-driving compactors.

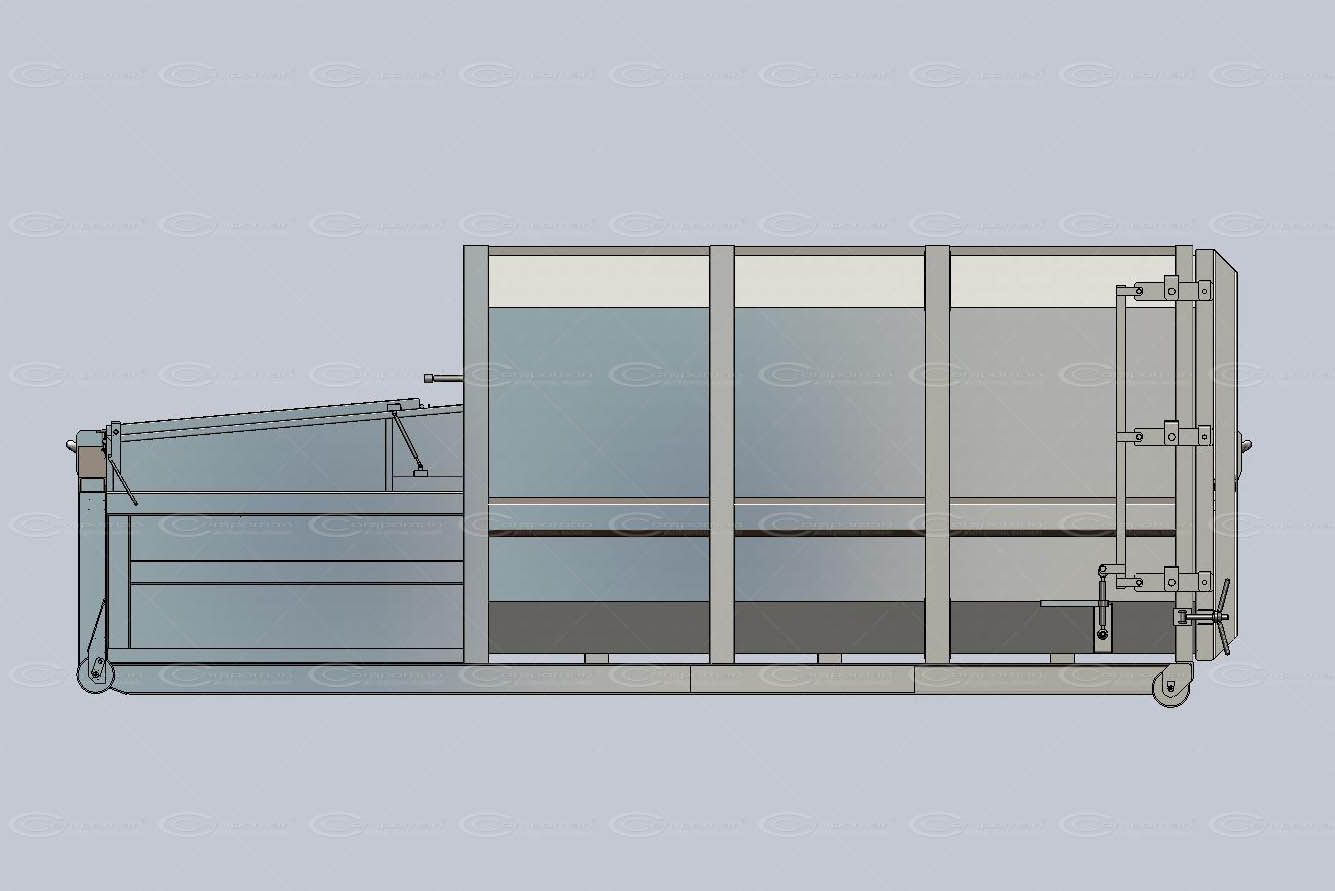

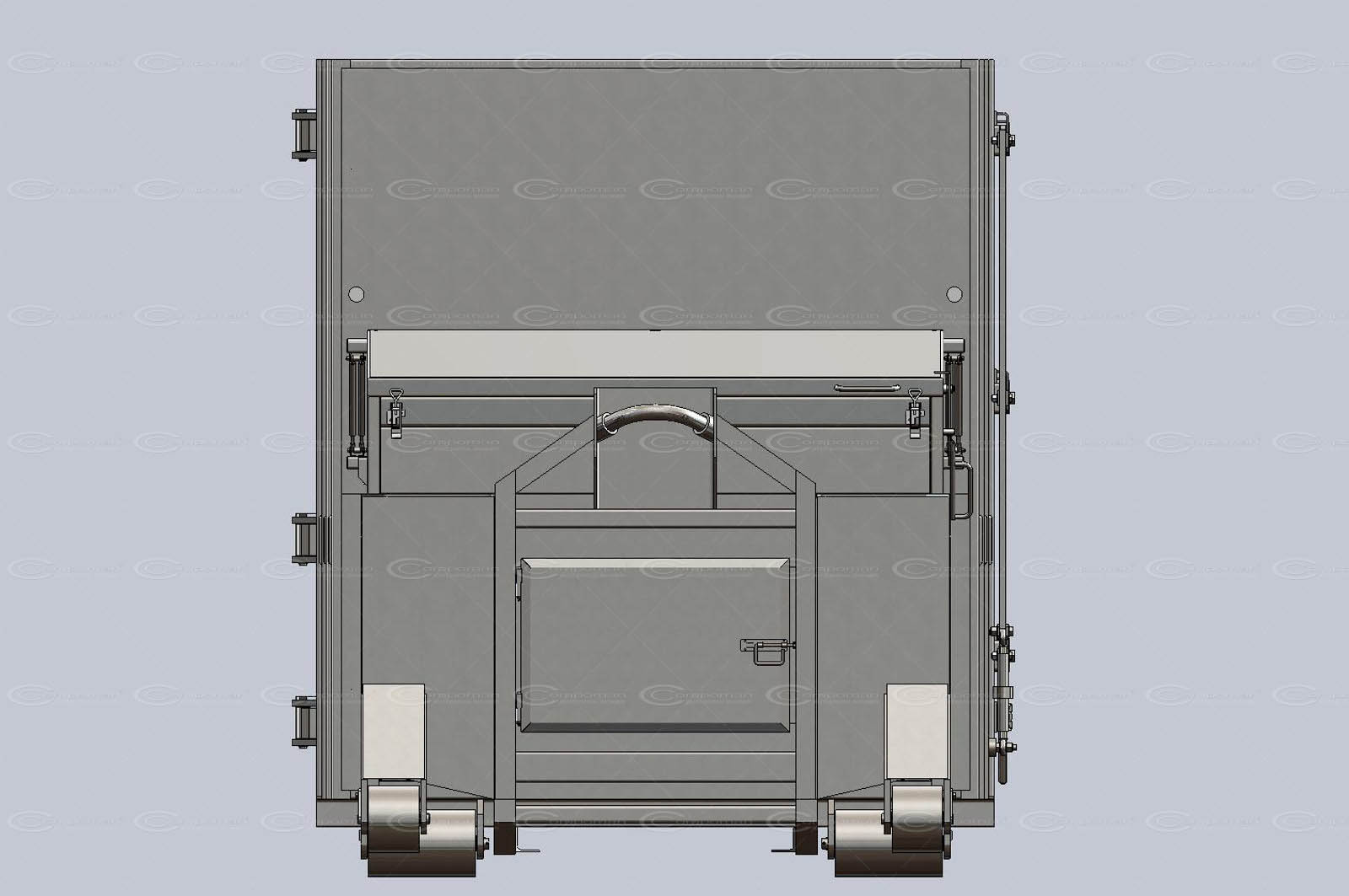

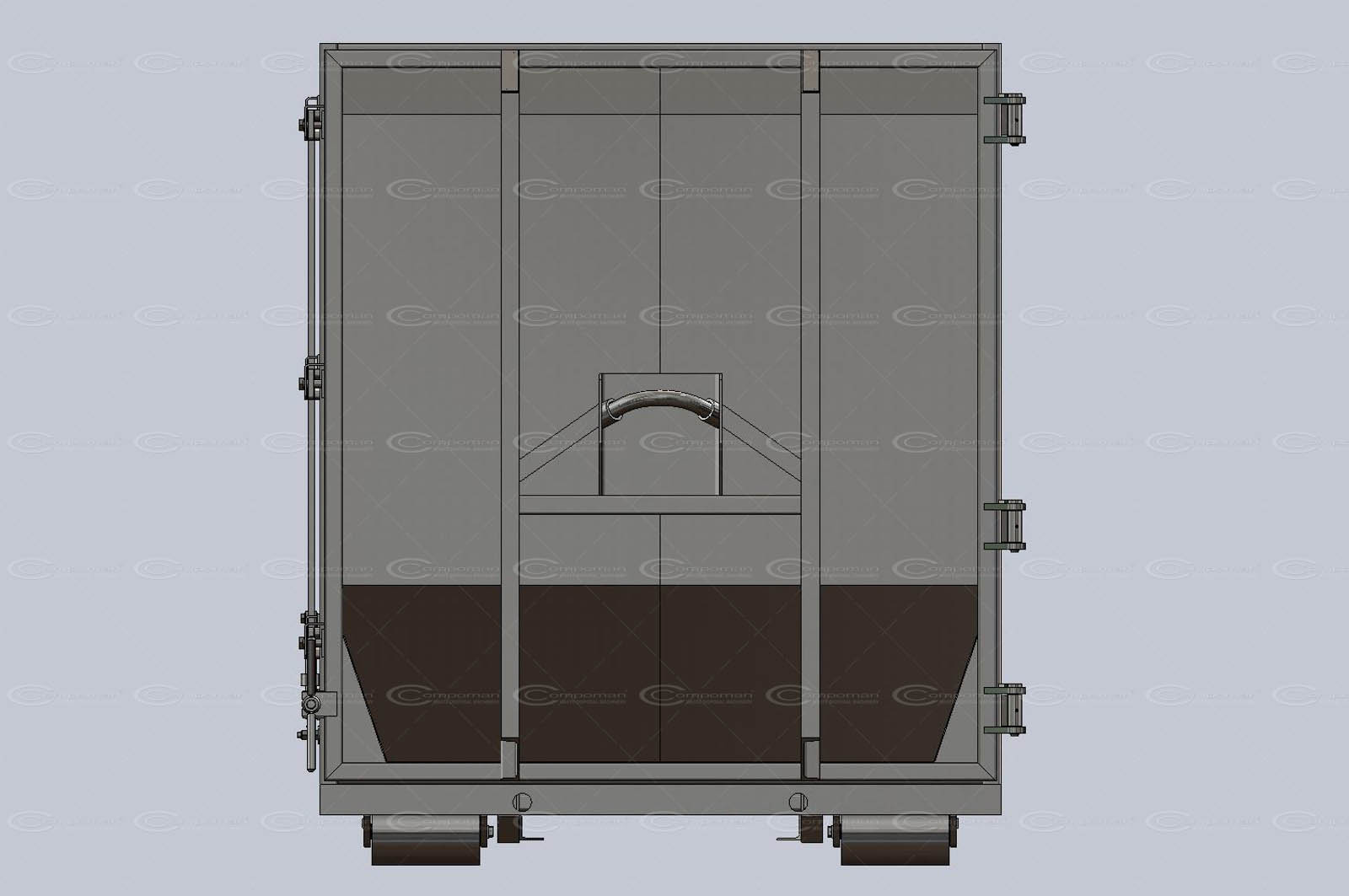

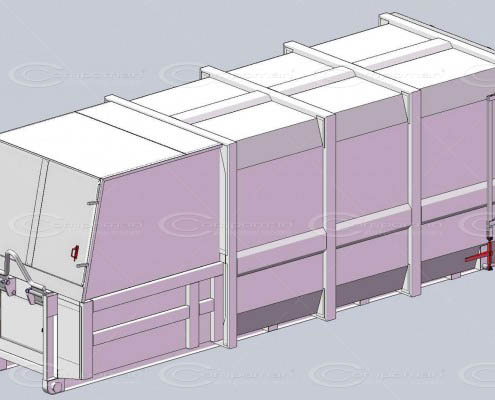

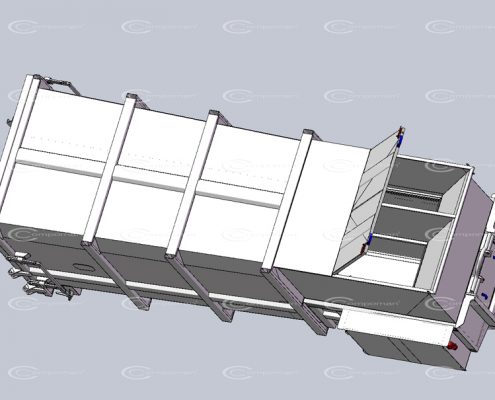

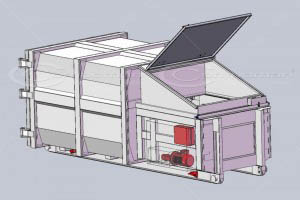

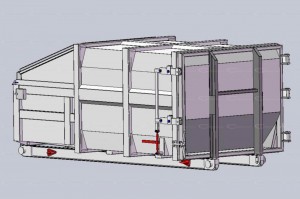

Mobile compactors riding on frames

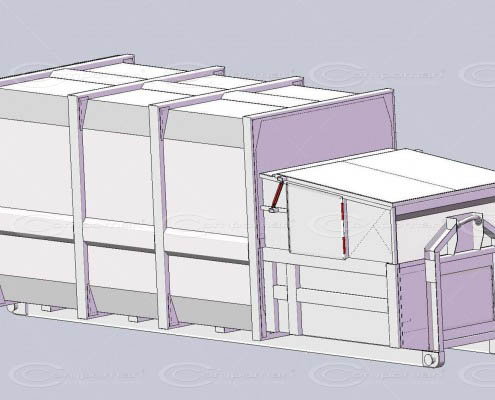

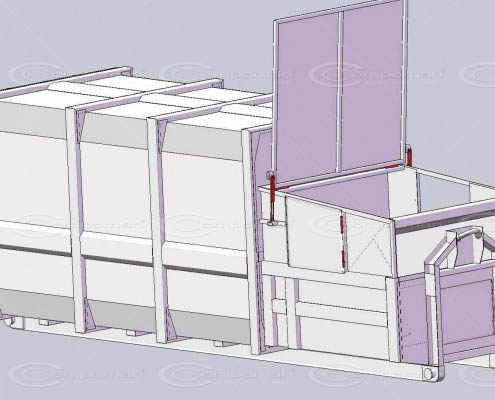

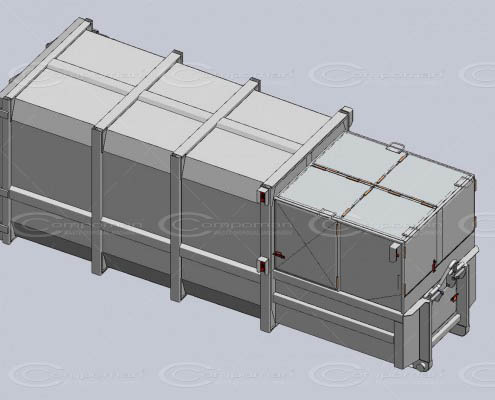

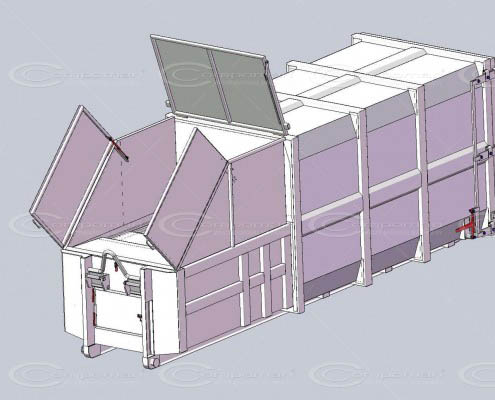

Some locations require innovative measures to ensure best possible placement of compactors with the most container capacity. This innovative solution must also ensure comfort for loading for the end users. For those demanding places we have created mobile compactors standing and driving on moving frame.

How does it function?

On the floor are rails. On the rails there is a moving frame with own reducer-motors and compactor is placed on that moving frame. This frame can move full compactor out of the loading positon into the position where the truck can come and pick the compactor up for emptying run. Compactor has loading position necessary for the end user – at the ramp or under the chute. Compactor will be driven out of that position into picking-up position when full.

Effective use of space

This solution ensures most effective use of space so that enough container volume and necessary compaction capacity is available for the end user. Below are photos and 3D pictures from two out of many we have produced. One solution was created for passenger ferry and the other for an industrial site.

Huge choice of additional equipment to choose from

Our optional list of additional extras is so comprehensive that we are confident that we can provide the solution you are looking for.

As a special highlight, we offer to equip our compactors with a weighing system or telemetric system or GPS system. We can install smoke detector on the compactor to increase safety on the premises.

GPS system with modem helps you track the current location of the compactor and the time it should be emptied with help of “pre-full indication” and “full indication” sensors.

Telemetric system collects all the compactor data over the internet connection to the server. It allows you to create reports of your compactors and look up waste weight in each of your compactor park.

Wide range of integrated bin lifters

Our integrated bin lifters are suitable for most common types of wheelie waste bins. We can provide integrated bin lifters for ground and ramp loading, from front end and from sides.

Our front ground loading integrated bin lifters come in three types: with comb, for pinion/trunnion bins and the combined solution.

Integrated bin lifter for ground or ramp loading

Our simplest and most popular bin lifter can be attached to the mobile compactor from 5 positions:

- ground loading on either side – from right and from left

- ramp front loading

- ramp loading on either side – from left and from right

This bin lifter is well tested and has been widely used over the years. It was one of the first bin lifter models developed in our company and it is continuously very popular among the partners.

Agree your own particular standard with us

You can agree with us all the finer details of your own standard machine. You can decide the set-up of your very own standard mobile compactor that has all those little extras according your specifications. This will then be your standard with us and you can order it whenever you are ready for the next compactor.

Below you see two partner’s own standard compactors.

Customized machinery to meet your exact specification

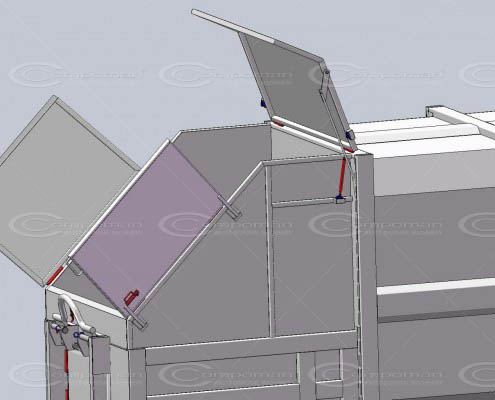

We can tailor our product range to meet your needs from hoppers and lids, opening mechanisms and dimensions, loading heights, motors and hydraulic systems. See here for photos of hoppers we have produced.

You will get your customized compactor delivered to you within the normal delivery time of a standard product. You can put together you own standard machine – you can choose your country’s standard, your preferred set of extras, speed and pressing power, your colour.

Below is the photo of a yellow compactor that can work both from truck electricity & hydraulics and from 400V electricity supply. It was produced to match a specific order from a customer.

Trust us to help you solve your waste handling problem

Compoman is your trusty partner if you have problem waste streams or if the site has complications or space constraints.

We can customize dimensions of machinery and modify accessories to fit. Don’t assume it can’t be done – call us +372 670 2401 and we can help.

We can solve your problem quickly by producing a customized product within the normal delivery time and price of a standard product.

Our expertise in mechanical engineering enables us to create innovative solutions, transforming your problems into opportunities and solutions. So you do not have to pay over the odds and wait for a specialized solution for your site.

Different countries and standards

All machines are delivered with a CE sign and a declaration of conformity. We supply to many European countries, according to their manufacturing specifications (DIN, CHEM etc.). Our compactors are equipped for transport– either with lifting hooks, lift dumper systems or skip lift systems.

Standard compactor models

| Type | Width | 11 m³ | 16 m³ | 18 m³ | 20 m³ | 24 m³ | Height with cooler |

| Height 2475 mm | Height 2650 mm | ||||||

| M10x08 | 2450 | 4750 | 6000 | 6000 | 6500 | 6925 | +160 mm |

| M15x08 | 2450 | 4550 | 5800 | 5800 | 6300 | 6725 | +160 mm |

| M15x10 | 2450 | 4750 | 6000 | 6000 | 6500 | 6925 | +160 mm |

| M18x12 | 2450 | 5125 | 6375 | 6375 | 6875 | 7300 | +160 mm |

| M18x15 | 2450 | 5350 | 6600 | 6600 | 7100 | 7525 | +160 mm |

| M18x17 | 2450 | 5500 | 6750 | 6750 | 7250 | 7675 | +160 mm |

| Radial 15X15 | 2450 | 4550 | 5800 | 5800 | 6300 | 6725 | +160 mm |

| Radial 17X15 | 2450 | 4550 | 5800 | 5800 | 6300 | 6725 | +160 mm |

| Screw 15×15 | 2450 | 4990 | 6240 | 6240 | 6740 | 7165 | +160 mm |

| All measurements and dimensions are given in mm

Measurements can differ and structural changes are made according to specific needs and demands. |

|||||||

Advantages of Compoman mobile compactor

Optional equipment

- Custom-made loading hoppers.

- Ram and charge box made with specially strengthened and wear-resistant steel.

- Ram and charge box made with corrosion-free steel.

- Ram equipped with scrapers.

- Ram made with special steel and without plastic wear plates to reduce maintenance costs.

- Hydro oil cooling assures that your compactor will withstand constant heavy duty use.

- Hydro oil heating keeps your compactor working when temperature is below zero.

- 100% full indicator and/or adjustable 75-80% full indicator and/or monitoring filling up of the container from 0% to 100%.

- Photocell or ultrasound sensor to start compacting process when charge box is full.

- GSM system to send 4 or more different error and informative messages to be received as SMS text or as e-mail.

- Change compactor settings or monitor performance whether as an SMS text, via mobile phone or via internet.

- Double pump or bypass system – increases cycle time

- Variable displacement pump ensuring optimal cycle speed and time.

- Extra-quiet hydraulic setup.

- Lifting unit at front or side, from the ground or from a platform, for customer-specific bins with lifting speed and lifting capacity to order.

- Pre-crush plate (also with teeth) or wood crushing compactor option.

- Single or twin metal or aluminium lids for charge opening, with or without gas springs.

- Automatic, hydraulically-controlled lid opening and/or closing.

- Turning loading hopper enabling dock loading from different sides facilitating the reuse of the compactor in different locations.

- Fold-down front hook, low hook or standard hook in front

- Short or long guide rails or guiding plate to help the easy and repeated placing of a compactor

- Back door with top or side hinges, with partial of full rubber gasket.

- Colour coating of your choice, many types of paint available.

- Floating container part roof.

- Working hours counter.